| Associate Professor Yang Shengyuan - Prof. Zhu Meifang: Bottom-up wet spinning-electrospinning combined construction of sensory energy storage integrated intelligent fiber |

| 发布时间:2018-07-19 浏览次数:205 |

|

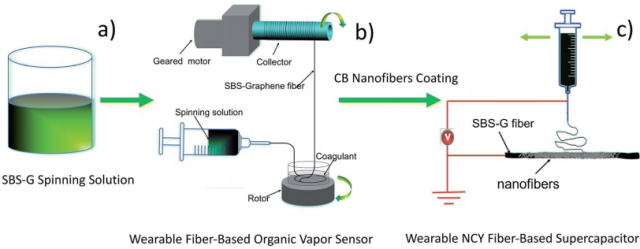

In recent years, with the rapid development of flexible wearable electronic products, flexible sensors and flexible energy storage elements have attracted widespread attention. As an important part of wearable electronic devices, flexible sensors and flexible energy storage components have great application prospects in the fields of human motion detection, personalized health monitoring and intelligent human-computer interaction. Among them, the flexible sensor should have high sensitivity, wide detection range, high flexibility and high stability, and the flexible energy storage element should have excellent electrochemical performance, good mechanical flexibility and the like. To date, the preparation of these desirable flexible devices remains a challenge. Flexible devices with excellent comprehensive performance are expected by selecting materials and adopting new preparation techniques and design ideas. Conductive polymer composite fiber-based flexible devices have become one of the important research directions of flexible devices due to their flexibility, light weight, foldable bending, woven, low cost and large specific surface area. However, the conductive polymer composite fibers prepared by the conventional spinning method tend to have low electrical conductivity and are difficult to be used in both the sensor field and the energy storage field. How to prepare a fiber-based flexible device with both sensing and energy storage functions through a simple, low-cost, and continuous method is still an urgent problem to be solved. Recently, Professor Dongmei Yang, Associate Professor of the State Key Laboratory of Fiber Materials, Donghua University, and Associate Professor Yang Shengyuan (Corresponding author), together with the National University of Singapore (NUS) and the Leibniz Institute of Polymer Research (IPF) in the Journal of Germany The latest research results A Bottom-Up Approach to Design Wearable and Stretchable Smart Fibers with Organic Vapor Sensing Behaviors and Energy Storage Properties were published on Materials Chemistry A (the latest impact factor 9.93) and were selected as the current back cover. The first author is East. Ifra Marriam (from Pakistan) and Dr. Wang Xingping from the School of International Cultural Exchange of the University of China (now working at Honeywell Shanghai). In this paper, the author uses poly(styrene-butadiene-styrene) (SBS) as the flexibility from the perspective of the spinnability, mechanical properties and functionality of the composite. A series of flexible SBS conductive composite fibers were prepared by wet spinning using a multi-layer graphene (FLG) as a conductive component. The structure and sensing of flexible SBS conductive composite fibers were systematically studied. The intrinsic relationship of performance realizes the organic unity of high flexibility and high performance of composite fibers. In addition, on the basis of flexible SBS conductive composite fiber, the research group applied electro-activated carbon black (CB) to the surface of SBS conductive composite fiber by electrospinning self-assembly method, thus producing a series of self-supporting. The flexible one-dimensional yarn electrode (Nanofibers Coated Yarns, NCY) was assembled into an all-solid supercapacitor, and its electrochemical performance was systematically studied to realize its application in wearable energy storage components.  Fig.1 Schematic diagram of the preparation process of wet-spinning-electrospinning combined from bottom to top

Fig. 2 Characterization of sensing performance of flexible SBS-G composite fiber for different solvent vapors

Fig.3 Characterization of electrochemical properties of flexible SBS-7G, SBS-7G@CB and SBS-7G NCY electrodes In summary, the researchers combined the previously wet-spun composite fiber sensors (Composites Part A, 2018, 105, 291–299; Sensors and Actuators B, 2018, 256, 896–904) and electrospun coated nanofiber yarns (ACS Appl Energy Mater., 2018, 1, 377-386 (Front Cover); J. Power Sources, 2018, 396, 683-690) successfully designed a macro by bottom-up wet-spinning-electrospinning (Wet-spun macro fiber) Micro (electrospun nanofiber) combined with intelligent fiber that has both sensing and energy storage functions, is expected to be further applied on wearable devices.

Shengyuan Yang, Meifang Zhu et al., J. Mater. Chem. A, 2018, 6, 13633. (当期封底) The work was funded by the Shanghai Chenguang Project, the Shanghai Science and Technology Innovation Action Plan, the National Natural Science Foundation, the Ministry of Science and Technology Key Project, and the Innovation Team of the Ministry of Education. |