| Professor Zhu Meifang, Associate Professor Yang Shengyuan: Self-assembly of nanofibers based on electrospinning for ultra-flexible energy storage |

| 发布时间:2017-12-24 浏览次数:85 |

|

Recently, Associate Professor Yang Shengyuan and Professor Zhu Meifang published their latest research results on ACS Applied Energy Materials: Surface Self-Assembly of Functional Electroactive Nanofibers on Textile Yarns as a Facile Approach Towards Super Flexible Energy Storage, co-authored by Mike Tebyetekerwa (from Uganda) and undergraduate students from the College of Materials. Xu Xu (currently studying for a doctorate at Queen Mary University of London, Queen Mary University, London, UK). In this paper, by electrospinning and using stainless steel yarn as the receiver of nanofibers, polyindole/carbon black composite nanofibers were self-assembled and wrapped on stainless steel yarns by electrostatic adsorption, and ultra-flexible linear electrodes were fabricated. A series of previous works (Materials Letters, 2017, 209, 400-403; Electrochimica Acta, 2017, 247, 400-409; J. Mater. Chem. A, 2017, 5, 21114-21121) have systematically studied the potential applications of polyindole nanofibers and their composites in energy storage devices such as supercapacitors. The linear super-flexible electrodes of polyindole and its composites were fabricated by this new but simple process. After knitting or knitting the linear electrodes into the fabrics, it was found that the specific capacitance of the electrodes did not change significantly. To a certain extent, this process has a good application prospect in the design of wearable flexible devices. That is, this method can be used to fabricate flexible and intelligent yarns of various textiles. The electrochemical properties of PET fibers can be further improved by compounding with carbon nanotubes, graphene and MXene (Joule, under review). Relevant research work has been supported by Shanghai Morning Light Plan, Shanghai Science and Technology Innovation Action Plan, National Natural Science Foundation and National Key R&D Program. Figure 1 Process flow diagram

a-c) Preparation of Spinning Solution d)Linear electrodes were prepared by electrospinning, in which SSY was stainless steel yarn and NCY was nanofiber coated yarn. Figure 2 Material Characterization

a)FTIR diagrams of polyindole, carbon black and polyindole/carbon black (mass ratio 1:4) composites,b)Raman diagram of polyindole, carbon black and polyindole/carbon black (mass ratio 1:4) Composites,c) TGA diagrams of polyindole, carbon black, polyindole/carbon black (mass ratio 1:4) composites and PVA Figure 3 SEM and elemental mapping analysis of NCY-Pind/CB 1-4

a) Surface and b) Enlargement of NCY, c) Section of NCY, d-g) Element Mapping Analysis of NCY Fig 4 Assembly and electrochemical performance diagram of supercapacitors

1-3) Assembly schematic diagram of supercapacitors, a) CV diagram of superelectric properties of polyindole/carbon black nanofibers with different ratios, b) GCD diagram, c) specific capacitance at different scanning rates, d-e) EIS diagram Fig 5 Electrochemical Chart of Supercapacitor

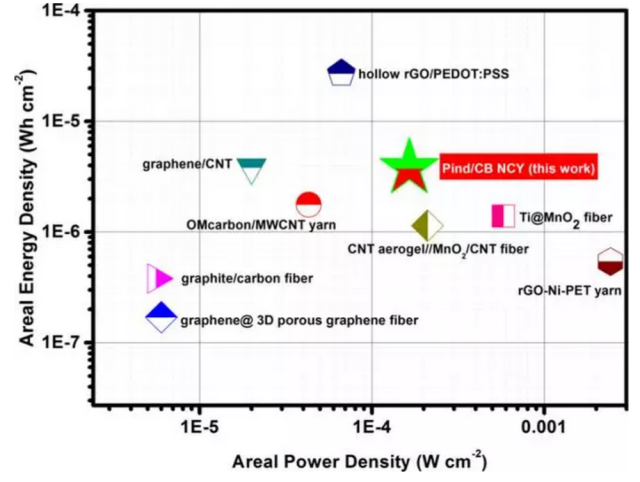

a) CV diagrams of polyindole/carbon black (mass ratio 1:4) composite nanofibers at different scanning rates, b) GCD diagrams, c) area specific capacitance and linear specific capacitance, d) cyclic performance diagrams and e) flexibility tests - CV diagrams under different braiding modes Figure 6 Area power density and energy density comparison with other linear supercapacitors  Thesis link: http://pubs.acs.org/doi/10.1021/acsaem.7b00057 |